Why do we need to make our can sealing machine driven by servo motor, digital control, what are the benefits?

In order to ensure excellent sealing performance of cans, according to the diameter and height of the can and the size of the lid to tailor made mold

Chuck head after heat treatment

According to the tank diameter and height mapping customized turntable

According to the diameter and depth of the cover, the cover dropping device is customized

In order not to make mistakes in the sealing process, but if the mold position in the process of sealing can——In other words, there is a deviation in positioning, what will happen?

the jar gets stuck, or the lid is crooked, the scrap rate has increased explosively, damage to products and equipment

So what controls the positioning of the mold?

Let's talk about how the pure mechanical control structure controls the positioning of the turntable

Cam divider is a mechanism to realize intermittent motion, the application of can sealing machine is to divide the working state into two parts, there are two kinds of status: sealing and incoming.

The important factors affecting the segmentation accuracy and life of the divider——Adjustment.

The splitter is a precision machined part, after careful assembly and debugging.If the debugging is not good, the segmentation accuracy will be affected, impact, noise, damage to the divider

It takes a lot of effort to choose the cam divider, at the same time, the cans is stuck due to foreign matters and other factors during the operation of the equipment, will cause pure mechanical control of the various parts of the equipment shutdown

Our first generation can sealing machine also adopts this structure

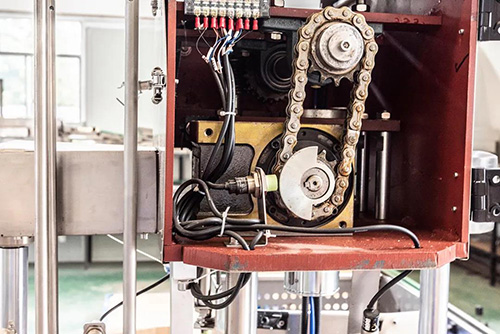

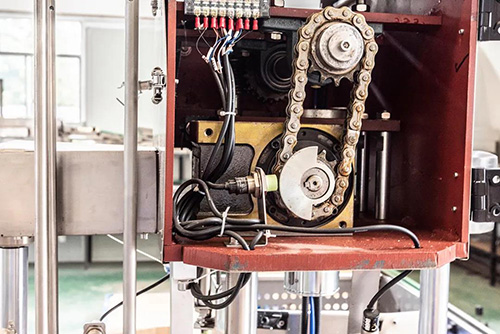

Internal structure of pure mechanical control

Finish pure mechanical control, next popular science digital control, servo control

The word servo is very unfriendly and difficult for ordinary people to understand

Take a simple example, you sit on the couch and watch TV, your wife told you to throw away the garbage, you went downstairs with the garbage bag.

In this servo system, "Your wife" is the controller, Your wife says to you, "husband, go and throw away the garbage.", This is a program written by an electrical engineer, And "you" is the servo motor, you carry the garbage bag in your hand, complete the process of rising and falling, swinging left and right, and finally entering the garbage can

The first advantage of servo control:

the first is high accuracy, one turn of the servo motor can reach thousands to millions of pulses, your wife is 5 meters away from you and says, "I'm going to wear green today!" And your wife 5 meters away from you and say: "I'm going to wear 20 wardrobes inside the No. 3 cabinet, which is the third green coat on the 7th floor from the left!"

Do you understand the accuracy? Help to find clothes quickly!

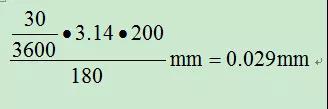

The positioning accuracy of the divider can reach ± 30sec (pay attention to the fact that it has a lot to do with the manufacturer) If the diameter of the turntable is 400mm, first turn the positioning accuracy to an angle of 30 / 3600 degrees. Then use the formula arc length to calculate, the final error is 0.029mm,

The accuracy gap is very large, High precision brings accurate mold positioning, The sealing performance of the tank is excellent, It is very important for quality control, and then affects the reputation of the brand

The second benefit:

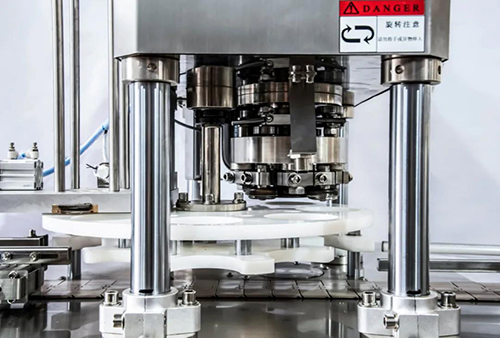

This is a picture of the second generation servo sealing machine

This is a picture of the first generation of pure mechanical control can sealing machine with cam divider

The structure of pure mechanical control must be lubricated, The newly added lubricating oil is a yellow paste, viscous liquid, After friction and oxidation, dust and other factors will affect, Emulsification and blackening, Can food industry, health care products industry and medical industry accept it? This is a packaging and sealing device!

Servo motor control will not bring the above secondary pollution risk

The third benefit:

Once the tank is jammed in the pure mechanical control structure, the internal mechanical components will be "hard hit hard", Wear, dislocation, many problems have come, The bicycle chain will not be replaced even if it is lost, and you still have to repair and seal the can machine. Maintenance and re debugging are very complicated and troublesome, and have a great impact on production

Servo control and digital control are different, Through structural design and program control, it has the function of moment detection, It can judge the abnormal operation of the can and stop the machine automatically. For example, it's easy to understand, You and your wife are at home wrestling to decide who does the dishes tonight, You are a fitness lover, As soon as you start to work, you will find your eight powerful brothers in law standing behind your wife, You quickly take back the strength of your arm, So your wife can avoid an arm injury, "You" is able to detect "force", can stop and continue to "force" in time to avoid "hard hitting hard", This can play a good role in protecting equipment. After removing the abnormal can body, A quick check will allow production to continue, The cost of operation and maintenance in the later stage is greatly reduced.

In fact, from pure mechanical control to servo control, Now, a new generation of digital control

For more information, please contact:

Email: [email protected]

Whataspp/Wechat: +86 15800042255