China is a traditional agricultural country with a history of thousands of years since the Neolithic age. As one of the pillar industries in China, agriculture is an important part of the national economy. According to statistics, China's rural population is about 560 million, accounting for about 40% of the national population. Therefore, we should promote the upgrading of agriculture.

China's agriculture consists of planting, forestry, animal husbandry, fishery and sideline industries. Because our country has been in a state of large population and relatively small cultivated land area for thousands of years, our agriculture is mainly planting, and food production is the top priority!

Geographically, China is located in the east of the Eurasian continent and the west coast of the Pacific Ocean, which can produce huge differences in the thermal properties of the land and sea, thus forming the most typical monsoon climate in the world. The main characteristics of this climate are high temperature and rainy in summer, cold and less rain in winter, and the high temperature period is consistent with the rainy period. In summer, it is hot, humid and rainy, which is very beneficial to the growth of crops, especially rice!

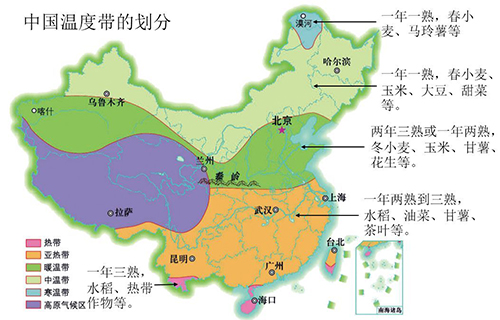

Rice planting in China is mainly distributed in the Yangtze River Basin, Pearl River Basin and Northeast China, and the northernmost limit is huma, Heilongjiang Province. Due to the differences of regional climate, the time of rice production and harvest will be affected, such as "one crop a year", "three crops in two years", "two crops a year", and even "three crops a year". Rice becomes edible rice after cleaning and grinding.

Rice brick is fresh-keeping by vacuum technology. Which technology is used for Canned Rice? Because the tank is also a very closed space, it can isolate most of the influence of moisture. If there is oxygen in the tank, it will react with rice to produce oxidation reaction, greatly shortening the storage life of rice. In order to reduce oxygen, we can use vacuum nitrogen filling or direct dripping liquid nitrogen to drive away oxygen as far as possible and replace the original position of oxygen with nitrogen. Because nitrogen is an inert gas, it does not react with rice, so it can extend the shelf life of rice.

According to the output, it can be divided into semi-automatic vacuum nitrogen can sealing machine and automatic rice can filling production line.

Semi-automatic vacuum nitrogen can sealing machine

Refer to the following video for details

characteristic:

1. Adopt the latest generation of mechanical design, the can body does not rotate in the sealing process, only the sealing hob rotates to complete the sealing, which is reliable and safe, especially suitable for fragile products and liquid products;

2. There are two working modes to choose from: vacuum nitrogen filling sealing and vacuum sealing;

3. Under the vacuum nitrogen charging mode, the residual oxygen can reach below 3% after sealing, and the maximum speed can reach 6 cans / min (the speed is related to the size of the tank and the value standard of residual oxygen)

4. The hob and indenter are made of 440C stainless steel, which is not easy to rust and has a hardness of more than 55 degrees. It is more durable than traditional chromium 12 material and has a service life of more than 6 million cans;

Automatic rice canning line

Refer to the following video for details

What kind of equipment does the automatic rice canning line consist of?

Supporting equipment are: manage bottle machine, particle material filling and weighing system, liquid nitrogen filling machine, can sealing machine

1. Bottle unscrambler

Function: lead empty can into conveyor belt / end of production line to collect finished products

Bottle management speed: 30-40 cans / min

2. Filling and weighing system for granular materials

This filling system is equipped with material elevator, combination scale and rotary table feeder.

Function: through pouring nuts to the hopper of the elevator, the elevator will lift the materials to the combined scale, and then the combined scale can accurately measure, weigh and fill, and receive nuts in the fixed jar of the feeder.

Filling speed: 30-40 cans / min

3. Liquid nitrogen dosing machine

Function: add liquid nitrogen into the bottle, and then the liquid nitrogen is quickly gasified into nitrogen to achieve the effect of nitrogen filling and preservation

Filling speed: 400 bottles / min

4. Can sealing machine

Function: seal the lid of plastic can or iron can

Speed: 35 cans / min

For more information, please contact:

Email: sales3@utrustpack.com

Whataspp/Wechat: +86 15800042255