The Highlight of Utrusrpack's Can Sealing Machine

Utrustpack has been focusing on food packaging automation for more than 20 years, especially in the field of food can packaging, and has accumulated profound technology and experience. The sealing machine equipment of Utrustpack is characterized by stability, high efficiency, easy operation, convenient adjustment and energy saving, and is one of the important production equipment in the food, pharmaceutical, chemical and other industries.

The sealing machine of Utrustpack has a wide range of applications and can be used for sealing various specifications of cans, such as aluminum cans, tin cans, aluminum alloy cans, plastic cans, paper cans, and other round-shaped cans.

Utrustpack's self-developed semi-automatic can sealing machine, fully automatic can sealing machine, fully automatic vacuumizing and nitrogen filling can sealing machine and other series of products adopt PLC control, which can automatically complete the operations of can holding, lid dropping, can sealing, etc., reduce the manual operation part, and can be connected to the production line for use, effectively improving the production speed and efficiency.

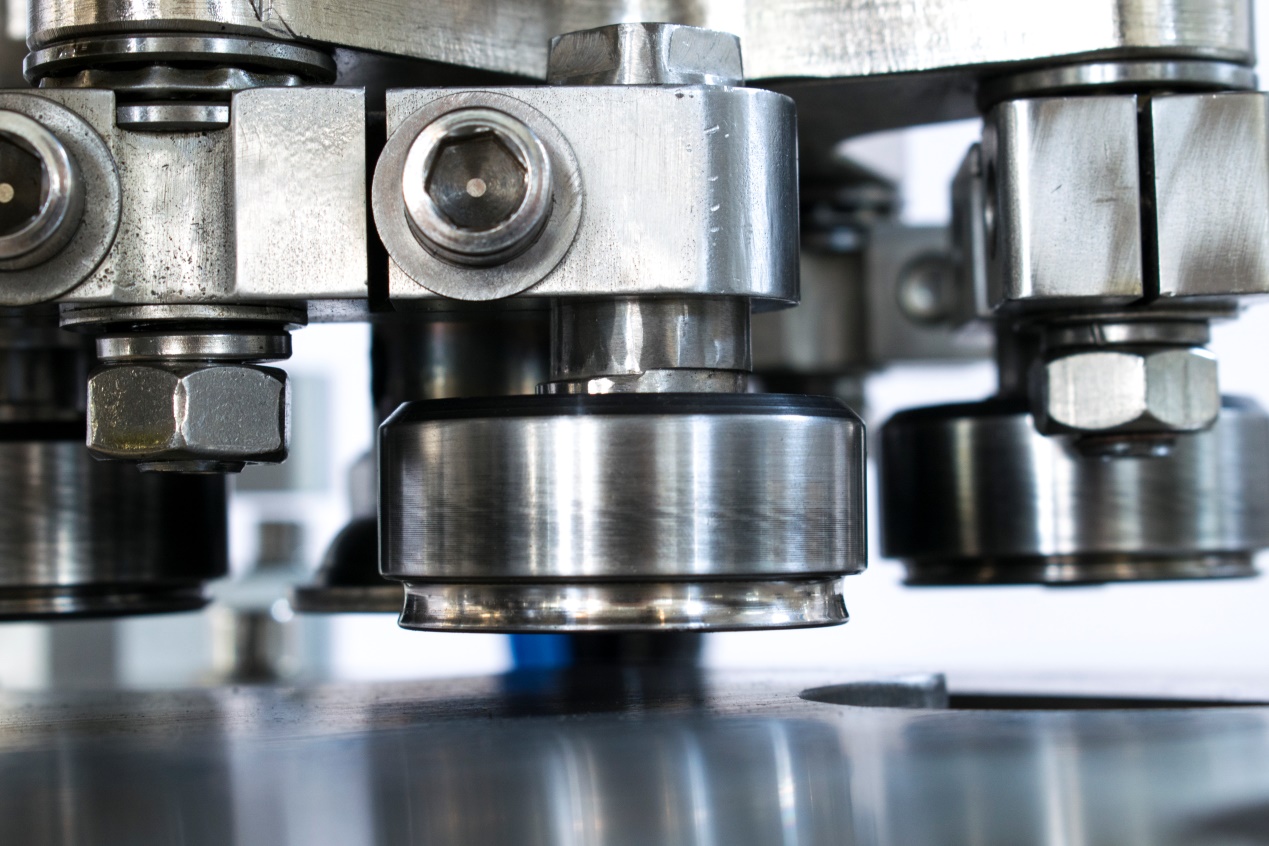

The sealing machine is made of thick and sophisticated materials, with advanced and precise processing technology, ensuring the overall quality and thickness of the equipment, thus ensuring smooth operation of the entire machine.

The operation interface adopts visual settings, and the touch screen operation is intuitive, simple, and easy to adjust parameters. One-button start, one-button reset and other settings can be quickly put into use.

The can sealing machine is made of food-grade stainless steel, which meets the requirements of food and drug hygiene. The safety protection devices such as cover-free parking can ensure the safety and stability during the production process.

The can sealing machine adopts frequency control and PLC control technology, which can automatically adjust the operating speed and production efficiency according to production needs, achieving high efficiency and energy saving.