In daily life, there are many food are packaged with plastic products, such as plastic bags, plastic bottles. Because of its relatively low cost and simple packaging, many food manufacturers like to use plastic bags. The cost of plastic bottles is relatively high, but the packaging is relatively beautiful, and can be used to hold other items after consuming the food in the bottle. More and more food manufacturers begin to use plastic bottle packaging.

Plastic bottle packaging may be divided into several ways, screw cap, seal easy to pull. If the screw cap packaging is selected, the sealing can be completed by manual capping. However, if the packaging method of sealing easy to pull is selected, the sealing principle is the same as that of the traditional iron can, and the can sealing machine must be used to complete the curling sealing. To understand the principle of sealing, you can browse Do you know how canned food is sealed?

There are many types of can sealers. We generally divide it into automatic and semi-automatic. Automatic type, easy to pull cover automatic cover device, conveyor line to achieve full-automatic. Semi automatic type, usually to manually put the lid and then put the tank, and then press the switch to start. For the production requirements of large, of course, choose automatic payment, the hourly production capacity from thousands to tens of thousands of cans. For customers with low production requirements, semi-automatic payment is the best choice!!

Semi automatic can sealing machine is a classic product of Guangzhou Utrust Packaging Equipment Co.,Ltd. It is like the corolla in the car to Toyota, which is stable and practical with long service life. Let's introduce this classic product:

1. Two sealing wheels are used for sealing, the first seam roller completes the curling and the second seam roller completes the blank pressing. The structure is simple and the adjustment is convenient; (4 seam roller can be selected.)

2. The latest generation of mechanical design is adopted. During the sealing process, the tank body does not rotate, and the sealing hob rotates to complete the sealing, which is reliable and safe, avoiding the displacement and scattering of the packed products in the tank, especially suitable for the sealing and packaging of fragile products and liquid products

3. The service life of the steel is more than 1 million;

4. The roller is made of 440C stainless steel roller, with a service life of more than 6 million times of sealing times

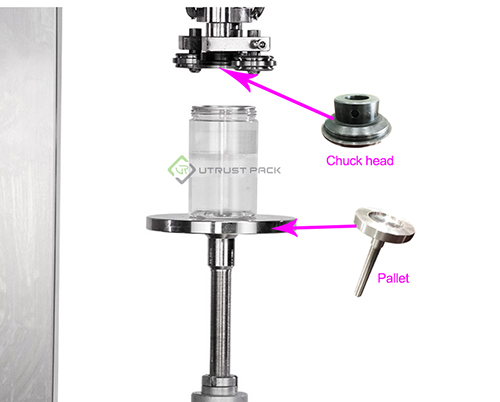

5. The die should be replaced when changing the diameter: chuck head + pallet, and the replacement time is about 10-20 minutes

6. Change the height of can sealing, no need to replace accessories, use manual rotation support rod, adjustment time is about 5 minutes. If the height difference of the jar is too large, the supporting rod needs to be replaced.

7. Simple operation, two modes are available: single sealing and automatic fixed frequency sealing.

For more information, please contact:

Email: [email protected]

Whataspp/Wechat: +86 15800042255