Nuts are familiar to all. There are many common nuts in life, such as chestnut, Castanea henryi, thunderbolt nut, hazelnut, cashew nut, walnut, melon seed, pine nut, almond, ginkgo, pistachio, Bigen fruit, desert fruit, Torreya, white melon seed, pumpkin seed, peanut, almond, Macadamia, etc. Nuts are the essence of plants. They are rich in protein, vitamins, lipids, and so on. They are very nutritious and have great effects on human growth and development, physical fitness and disease prevention.

Nowadays, there are many brands selling nuts, such as "3songshu", "qiaqiafood" and "Be Cheery" daily nuts. The price of nuts is very high. It costs dozens of yuan per kilogram in bulk. However, the packaging of some brands mentioned just now is very exquisite, some in bags and some in cans. They all pay attention to control the quality of raw materials from the source, and then publicize the locking technology used in packaging, so that their nuts can be different!

Among them, "qiaqiafood" nuts are also marked with "master key preservation technology", and "milk powder like fresh-keeping packaging" and "oxygen content < 1%"!!! Next, we analyze how to implement it technically.

The choice of the packaging of nuts will also affect the "taste" of nuts. At present, the packaging types of floss are mainly plastic bags and cans. The first use of plastic bag packaging is relatively convenient, but for secondary storage, it is more troublesome, the sealing is not good, and it is easy to cause nuts to get damp. Compared with the plastic bag packaging, can packaging is also conducive to the preservation after secondary use, which can better ensure that nuts are not susceptible to moisture deterioration. There are three types of can packaging, including paper cans, plastic cans and iron cans. The air tightness of iron cans is the best, but relatively heavy; the paper cans are lighter, but the air tightness is not ideal; and the plastic cans are between the first two, which are fashionable, environmentally friendly and transparent. Consumers will increase their desire to buy when they see food.

Why does "qiaqiafood" pack nuts like milk powder and oxygen content < 1%? Because nuts and milk powder are food with high protein content, it is easy to oxidize with oxygen, leading to deterioration. The milk powder with good quality is usually packed with nitrogen. Nitrogen is a kind of colorless and tasteless inert gas, which will not react with most substances such as protein. The oxygen content is less than 1% by filling nitrogen to replace oxygen, so that the milk powder can be stored for a long time!

It can be seen that the key technology is to increase the nitrogen content by reducing the oxygen content in the packaging container and then filling it. In practice, there are two ways to reduce oxygen content and fill nitrogen:

1. First put the jar into the closed container, then vacuumize, and then inject nitrogen into the whole container. Finally, seal the lid and open the container;

2. A small amount of liquid nitrogen is injected into the tank. After the liquid nitrogen flows to the bottom of the tank, it will rapidly gasify and expand into nitrogen, and then the other air in the tank will be driven out of the tank, so that the tank will be filled with nitrogen for a short time, and the oxygen content will be greatly reduced. At this time, the cover shall be sealed.

Liquid nitrogen, you may not be familiar with this thing. It literally means liquid nitrogen,

The difference between the two methods is that the first method needs to close the container first, then vacuumize, then fill with nitrogen and seal, which takes 6-10 seconds to complete; the second method only needs to spray liquid nitrogen and then seal the nut, which can be completed within 1 second at the earliest, and the high efficiency is obvious! Therefore, we suggest to choose the second method of packaging when conditions permit.

At present, Guangzhou Utrust Packaging Equipment Co.,Ltd has skillfully applied nitrogen filling technology and provided nut automatic canning and packaging scheme. According to the customer's customized requirements, it can be equipped with weighing, canning, nitrogen filling, sealing and other equipment, so as to improve product quality, reduce labor costs and improve efficiency for customers.

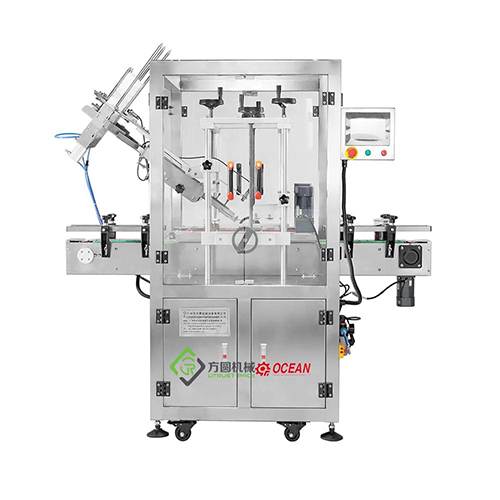

The figure below shows the packaging equipment for automatic canning of nuts, with production capacity ranging from 35-45 cans / min.

What kind of equipment does the automatic canning production line consist of?

Equipment: bottle management machine, filling and weighing system for granular materials, can sealing machine, plastic capping machine / capping machine, labeling machine

1. Bottle unscrambler

Function: lead empty can into conveyor belt / end of production line to collect finished products

Bottle management speed: 30-40 cans / min

2. Filling and weighing system for granular materials

This filling system is equipped with material elevator, combination scale and rotary table feeder.

Function: through pouring nuts to the hopper of the elevator, the elevator will lift the materials to the combined scale, and then the combined scale can accurately measure, weigh and fill, and receive nuts in the fixed jar of the feeder.

Filling speed: 30-40 cans / min

3. Liquid nitrogen dosing machine

Function: add liquid nitrogen into the bottle, and then the liquid nitrogen is quickly gasified into nitrogen to achieve the effect of nitrogen filling and preservation

Filling speed: 400 bottles / min

4. Can sealing machine

Function: seal the lid of plastic can or iron can

Speed: 35 cans / min

5. Snap lid applicator

Function: automatically press the lid to the top of the tank

Speed: 30-50 cans / min

6. Labeling machine

Function: paste the label to the can body.

Labeling speed: 30-40 cans / min

For more information, please contact:

Email: [email protected]

Whataspp/Wechat: +86 15800042255