At present, what is a fashionable way to maintain the ideal body shape? For each student party, office workers, fitness master, the answer is to eat meal replacement powder.

There are so many kind of meal replacement shakes in the market, like chocolate flavored nutritional drink, Mixing with raw organic ashwagandhaa & raw green coffee bean extract etc.

It is said that these meal shakes are high in protein, high in dietary fiber, and various vitamins and nutrients, so as to achieve the effect of reducing weight and shaping the body by controlling the amount of food, with low calories and a sense of satiety for several hours.

There are many kinds of meal replacement shakes on the market. For convenience, most of them are packed in dozens of grams, or packed in 1kg cans and bottles.

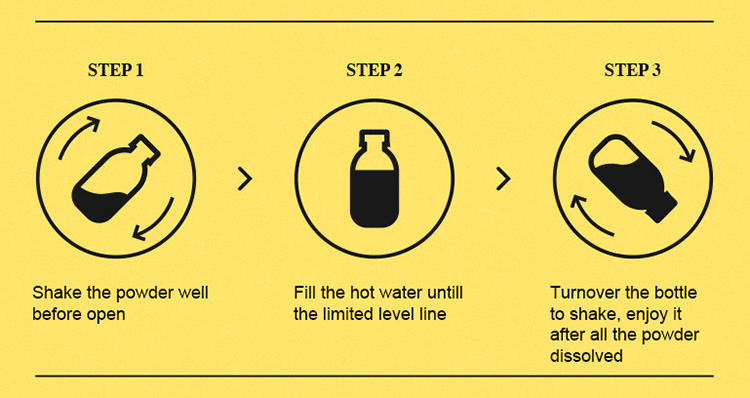

The stick pouch packaging is easy to carry, but there is a drawback: you need a cup or bowl when you drink, it is inconvenient for office lady, fitness master and student to enjoy it. So now there is a new packaging trend: in order to be able to take it with you and drink meal shakes at any time, the powder would be pre-fill into a PP bottle, you can fill hot water into the bottle for mixing, cover the lid and shake it to make the powder fully dissolved in water, then you can drink it immediately.

This packaging is very popular among the younger generation and office workers, so many manufacturers also want to package their meal replacement products in bottles for better sell. How to pack the meal shake in bottle?

Guangzhou Utrustpack would give you the suitable solution according to your requirement.

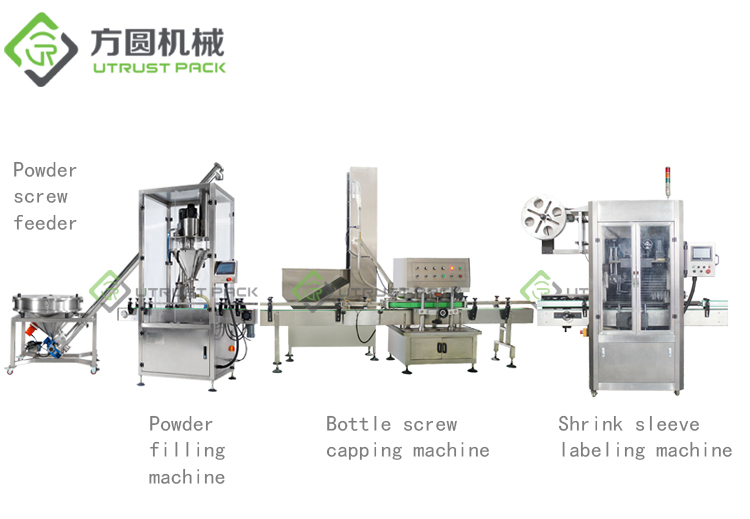

Here is the instruction of the automatic bottle packing line for meal replacement shakes:

Bottles unscrambling—dry fruit particle filling—shakes powder filling—liquid nitrogen dosing—bottle capping—shrink sleeve positioning—heat shrink…

1. Bottle unscrambler

Function: put the disordered plastic round bottles and flat bottles into the hopper. After the bottles are transported and sorted, the bottles would be automatically feed into the conveyor of filling machine

Feeding speed: 50-80 bottles / min

2. Weight and filling system for superfood particle

This filling system include bucket elevator, multihead scale and turntable filling machine.

Function: pouring the superfood to the hopper of the elevator, the elevator can lift the material to the multihead scale, and then the multihead scale can accurately measure, weigh and fill, and receive the superfood at the turntable filling machine.

Filling speed: 35-50 bottles / min

3. Double head powder filling machine

Function: using screw to accurately measure and fill meal powder

Filling speed: 30-45 bottles / min

4. Liquid nitrogen injector

Function: add liquid nitrogen into the bottle, and then the liquid nitrogen is quickly gasified into nitrogen to achieve the effect of nitrogen filling and preservation

Filling speed: up to 400 bottles / min

5. Bottle screw capping machine

Function: automatically feed the cap and screw the cap automatically

Capping speed: 40-50 bottles / min

6. Shrink sleeve labeling machine

Function: automatically put the shrink sleev label on the bottle body.

Labeling speed: 100-200 bottles / min

7. Heat shrink tunnel

Function: through hot air circulation, the shrink film label of the bottle body is heated to shrink

Production efficiency: 0-35m / min

For information, just contact [email protected], whatsapp: +86 15800042255