Min order:1

Payment: TT

Shipping Port: Guangzhou

Original Region:Guangzhou China

Lead Time:22 days after receiving deposit

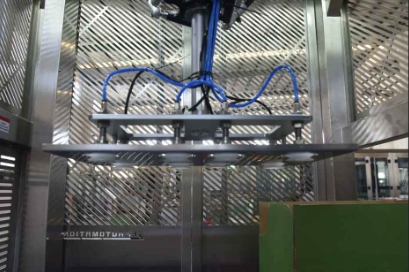

This equipment is a bagged chips picking robot 4 axis to sort the incoming products into the carton through the parallel delta robot according to the set arrangement. It can be used with carton erector and carton sealing machine.

Product show

Product parameter

| Number of axis | 3~4axis |

| Repeated positioning accuracy of delta robot | 1mm |

| Pick frequency | 30~60 pcs/min(according to the weight of the object) |

| Working radius | 1100mm |

| Maximum load | 8kg |

| Working voltage | 380v 20A |

| Power | 4.4KW |

| Weight | 800kg |

| Size |

1400*1650*2680(packing machine body) 1400*1650*2680mm(including conveyor belt) |

Show Details

*After installation and debugging only one key control start and stop

*Main body of this product is made of stainless steel

*The delta robots is used as the packing actuator

*Pick and place carton according to the set arrangement

Specification

1. The main function of this equipment is to put incoming products into the carton according to the set arrangement.

2. The main body of this product is made of stainless steel and up to food grade standard.

3. The delta robots is used as the packing actuator with high repetition precision and high working efficiency.

4. PLC servo motor control, to achieve accurate positioning + accurate grabbing.

5. The suction cup and gripper can be replaced according to different products.

6. The picking speed of 30~60 times/minute (according to the weight of the object), high production efficiency

7. After installation and debugging only need one button control to start and stop.

8. Fast disassembly structure design for switching to different tooling.

9. Customization for different electrical safety regulations such as CSA (Canadian Standards Association), Nemko or other standards, and must undergo strict inspection and testing before delivery.