With a sophisticated design, robust construction, and intuitive operation, this machine serves as a paramount and ideal packaging apparatus for the food, pharmaceutical, tea, and chemical sectors. By employing a sealing procedure that effectively lowers residual oxygen to below 3%, it substantially extends the shelf life of the products

Item NO :

UT1BFG6Original Region :

ChinaLead Time :

15 days after receiving samplesShipping Port :

GuangzhouPayment :

TTMin order :

1Product Introdution

This machine boasts a sophisticated design, a meticulously crafted structure, and effortless operation, rendering it an indispensable and exemplary packaging apparatus for the food, pharmaceutical, tea, and chemical sectors.

Manual Nitrogen Filling Can Seamer with Vacuum Function

Key Features

* Cutting-edge design ensures fixed cans during sealing, as only the sealing rollers rotate, providing reliable and secure sealing, particularly for delicate and liquid packaging.

* Sealing rollers and chuck head crafted from 440C stainless steel, offering exceptional hardness, corrosion resistance, and a lifespan of over 6 million cans or 5 years.

* Achieves residual oxygen levels below 3% through vacuum and nitrogen filling.

* Semi-automatic Vacuum Tin Can Closing Machine for Small Businesses accomplishes vacuuming, nitrogen filling, and sealing in a single operation within the vacuum chamber.

* Equipped with PLC control system and user-friendly touch screen interface for effortless operation.

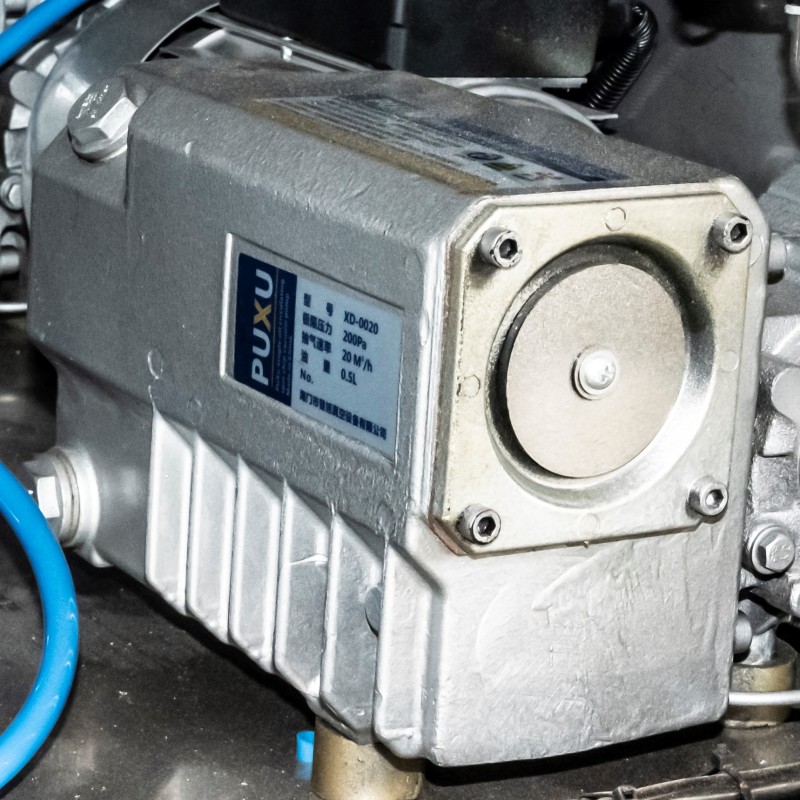

* Employs high-pressure vacuum pump to attain remarkably low levels of vacuum.

* Constructed with 304 stainless steel, meeting the highest standards of the food, pharmaceutical, and healthcare industries. Ideal for applications in the food, medical, chemical, and other related sectors.

* Electrical devices and pneumatic components sourced from reputable domestic and international manufacturers, ensuring dependable and consistent quality

Product Parameter

|

Function

|

Vacuum nitrogen filling tin canning, can seaming, can sealing

|

|

Sealing rollers

|

Rollers 1 pair (1st seam roll + 2nd seam roll)

|

|

Sealing Speed

|

5-6 cans/min

|

|

Sealing Height

|

40-190mm (adjustable)

|

|

Sealing Diameter

|

50-153mm

|

|

Voltage

|

220V,50/60Hz

|

|

Power

|

2KW

|

|

Weight

|

200KG

|

|

Dimension

|

750*1030*1700mm (L*W*H)

|

|

Air source

|

0.6-0.8 MPa

|

|

|

|

|

440C STAINLESS STEEL SEALING ROLLERS Eextremely hard and not easy to rust Service life is more than 6 million cans for 5 years |

PLC CONTROL AND TOUCH SCREEN SYSTEM Simple and easy to use Multi languages

|

VACUUM PUMP INSIDE THE MACHINE Built in pump Ready for vacuum |

|

|

|

|

VACUUM CHAMBER Vacuuming, nitrogen filling and sealing in the chamber at one go |

RESIDUAL OXYGEN CONTENT BELOW 3% Keep te freshness of the product Extend the shelflife of the foods |

OPERATING BUTTON Just press the two green buttons at the same time to seal the can |

Applications

Our Service on Semi Automatic Vacuum Tin Can Closing Machine for Small Business

* Inquiry and consulting support.

* Sample testing support.

* View our Factory

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

| 1.What is your installation services? | 2.What about your guarantee of quality? |

| User mauual and videos to surpport for installing,debugging,operation of the machine.It will indicate you how to use this machine well. | The Semi Automatic Vacuum Tin Can Closing Machine for Small Business is 1 year warranty,all machine part can be replaces within 1 year if broken(not including man made) |

| 3.If we have very special request for the production line,could you help me to do the design? | 4.Can I visit your factory? |

| Experienced mechanical designer customized-design provided. | Yes,welcome please. |

| 5.If we have samoles of new products,can you help to analysis and design the machine? | 6.Do you have certificate? |

| Yes.Our technical department can help to analysis design and test the new products you offered. | Yes,we have some,like CE/SGS. |