When it comes to canned food, many people think that it is a kind of fast food and has no nutritional value. The reason for this idea is that canned food is usually stored for a long time, and the food inside is not fresh, so it is not as good as the freshly cooked food. However, if you know the processing technology of canned food, the canned food can keep fresh for a long time, so canned food still has certain nutritional value.

When did can packaging appear? At that time, Napoleon of France led his army to fight in all directions. Because the front line was too long, a lot of food would rot and deteriorate after it was transported to the front line, and there was a problem with the supply. In order to solve the problem of food preservation, at that time, the French government used a huge prize of 12000 francs to seek a method for long-term storage of food. After constant practice, Nicolas Apel and his wife found a way: the food was treated well, then put into a wide mouth bottle, all placed in a boiling water pot, heated for 30-60 minutes, then plugged with cork while hot, then reinforced with wire or sealed with wax. This is the prototype of modern can.

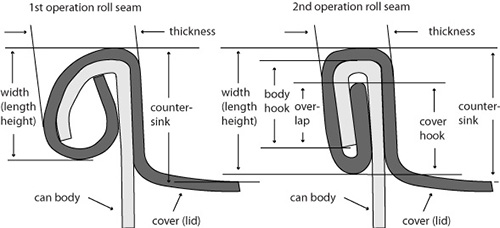

The cans on the market are made of iron, aluminum, plastic and paper. No matter which material is used, the can body and the cover are separated before sealing. Usually, the port of the can body has flanging, while the can cover has a round edge (in order to combine the sealing property of the part, a layer of sealant will be applied in the cap hook). The flanging of the can body needs to fit with the round edge of the cap. We need to use the can sealing machine (commonly known as the can sealing machine) to carry out the flanging of the can body and the round edge of the can cap in the sealing machine Roll seal, so that the can body and the can cover roll together with each other to form a tightly overlapped curling edge. The curling formed in this way is called double seam, and this packaging method is called double seam.

Now let's talk about the double seal in detail. In the can sealing machine, to complete the double winding seal, it mainly depends on four parts: the pressure head, the tray, the first roller (commonly known as "head knife") and the second roller (commonly known as "two knives") (refer to Fig. 1).

1. The function of pressure head: coordinate with the tank body and cover, fix the tank cover on the correct sealing position, and prevent the package from falling inside;

2. The function of the tray: by lifting up, the can body is positioned to prevent sliding, lifting and sealing

3. Function of crimping roller: the head knife makes the can body hook and cover hook bend and hook together, and the second knife presses and compacts the roll seal on the basis of the head knife

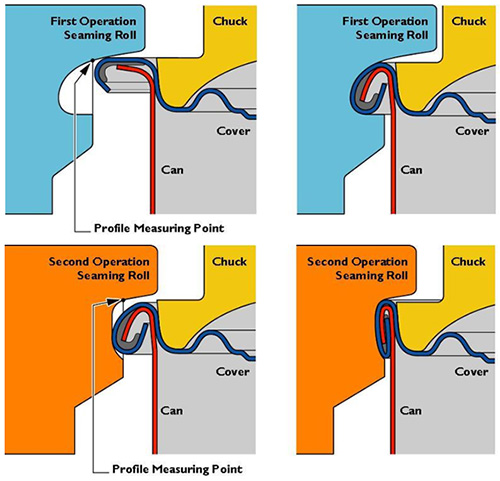

How do these four parts work together to seal? This process is divided into three steps:

1. Transport the can body to the tray, and at the same time, the tank cover falls on the tank mouth, and the tray rises, so that the can and the cover are tightly fixed between the ram and the tray;

2. Firstly, the head knife is pushed radially, and the cover hook is gradually rolled to the bottom of the body hook, and then the cover hook and the body hook are gradually bent, and the two hook together gradually to form a double hook edge, thus completing a double hemming

3. Then the head knife exits, and then the second coiling operation is carried out by the second knife. The hook groove part of the second knife enters and contacts with the formed flange. With the pushing action of the second knife, the cover hook and body hook are further bent and clamped, and finally reach the tight shaping state, forming a double hemming of five layers of material (three layers of can cover and two layers of tin body iron sheet are overlapped firmly).

You can watch the following pictures to understand the process of double sealing

(image from Internet)

Generally, the first step operation (the coiling of the head cutter) is the key to the whole double coiling. It can be said that 90% of the coiling work has been completed after the first step operation. If the defect caused by improper operation in the first step can not be corrected in the second step operation (roll sealing of two knives).

The first step is to check the roll seal regularly. In addition to measuring the external dimension, tearing and section analysis are also needed. The method is similar to the structure of the final roll powder. After the first step of operation, the wrinkles of the cover hook should be high frequency and low amplitude, and the ripple with high amplitude and low frequency will cause many winding defects (as shown in the picture)

The elements of judging the integrity of the package are as follows:

1. There are no visual defects;

2. The percentage of tightness indicates the correct tightness;

3. The overlap percentage of roll seal is correct > 55%

4. Body hook rate is correct 70% - 90%;

5. The shape of sealing glue, injection amount and distribution of sealing film are correct

In order to seal the cans well, in addition to understanding the basic principle of double roll sealing, we should also choose the appropriate can sealing machine (can sealing machine).

At present, there are two sealing methods for the can sealing machine on the market. One is that the can body rotates during the hemming process; the other is to test that the can body does not rotate, and two rollers rotate around the can mouth. The can sealing machine adopts the method of rotating the can body in the process of curling. The materials inside such as liquid are easy to overflow in the process of rotation, and some fragile solid materials can also be broken in the process of rotation. However, due to the number of rotations, the folding rate of curling is high. However, due to the insufficient number of turns of the roller, the folding rate of the curling edge is relatively less than that of the can body rotation. However, after repeated practice, Guangzhou Utrust Packaging Equipment Co.,Ltd. has reformed the mechanical structure to make the can body not rotate The fruit can be comparable to the can sealing machine with rotating can body. Please see the introduction of the automatic can seamer:

Function: seal the lid of plastic can or iron can

Speed: 35 cans / min