The liquid nitrogen (LN2) dosing system utilizing advanced cryogenic technology and PLC programming.

It can be used to immediately flush the air out of the container to minimize oxygen content and prolong the shelf life of the materials within the container. Meanwhile, it can increase the internal air pressure within the container for better transportation and storage.

Function and Advantage of the LN2

1. Nitrogen gas will be compressed into liquid nitrogen (LN2) under -195.8℃

2. LN2 will be turned into nitrogen gas when coming out from the LN2 injector, and 1 ml LN2 will be turned into 700 ml nitrogen gas, which will be immediately flush the air out of the container to minimize oxygen content and prolong the shelf life of the materials within the container. Meanwhile, it can increase the internal air pressure within the container for better transportation and storage.

3. Also, LN2 is widely used in food packaging industry because it can freeze the material immediately during gasifying period without destroying cellular tissue, so as to ensure the good tasting of the foods. Thus it is especially good for freezing meats, fish, ice cream and etc.

Features

The liquid nitrogen (LN2) dosing system utilizing advanced cryogenic technology and PLC programming. Three sensors detecting line speed, timing, and bottle presence allow the system to detect all lines speeds, including high speeds, to dispense a precise dose of LN2 into every container every time. The LN2 gasifies and is either trapped in the container to add rigidity or escapes with oxygen to inert the headspace.

1. Flexible Dosing Arm- allows the dosing head to be installed at any angle

2. Quick Service Automatic Defrost-eliminates most freeze ups in less than ten minutes

3. Precise Dosing- delivers consistent, accurate dosing over all lines speeds

4. Discrete Dosing - up to 1200 containers per minute

5. Discrete or Continuous Dosing - change over defined by user

6. Vacuum Insulated Technology- the most efficient use of LN2

7. SoftDose Compatible proven technology for hot fill,and granular applications.

Technical Parameters

| Material | Stainless Steel Series 300 |

| Weight | 38 lbs (17 kg) |

| Body Dimensions | 28.5"H x 6"W (724 x 152 mm) |

| Dosing Head Dimensions | 9.5"H x 2"W (241 x 50.8 mm) |

| Arm Reach | 24" to 34" (609.6 to 863.6 mm) |

| Head Pressure |

0.9 psi (0.06 bar) |

| Nozzles | Min. 0.020" - Max. 0.120" available |

| Ships | with 0.040" (installed),0.050", 0.060" |

| Liquid Nitrogen | 3 - 22 psi (0.2 - 1.5 bar) |

| Gaseous Nitrogen | 60 - 100 psi (4.1- 6.9 bar) |

| Electricity | AC 110 - 240V; 50/60Hz, 110W |

| Steady State Consumption | 0.04 gal (0.15 liter) / hour |

Product Details

Application

Contact supplier

Company Information

Guangzhou Ocean Automation Equipment Co., LTD. is a professional production and sales enterprise involving in various packaging automation equipment. The company integrates research and development, design, production and sales business, and the products sell well all over the country, mainly to packaging plastic materials laboratories, tea, food, beverage, medicine and other industries. The company is located in the core center of Guangzhou City in southern China, and has won good reputation through 20 years’ experience in packaging machinery production. We will as always focus on machinery production with rigorous and creative way, to serve customers around the world.

We will as always focus on machinery production with rigorous and creative way, to serve customers around the world.

* Inquiry and consulting support.

* Sample testing support.

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

| FAQ | |

| 1, What is your Installation Services? | 2, What about your Guarantee of quality? |

| User manual and videos to support for installing, debugging, operation of the machine, it will indicate you how to use this machine well | The Liquid Nitrogen Injector/Liquid Nitrogen Dispenser/Liquid Nitrogen Doser is 1 year warranty, all machine part can be replaced within 1year if broken (not including man made) |

| 3, If we have very special request for the production line,could you help me to do the design? | 4, Can I visit your factory? |

| Experienced mechanical designer customized-design provided. | Yes, welcome please. |

| 5, If we have samples of new products, can you help to analysis and design the machine? | 6, Do you have certificate? |

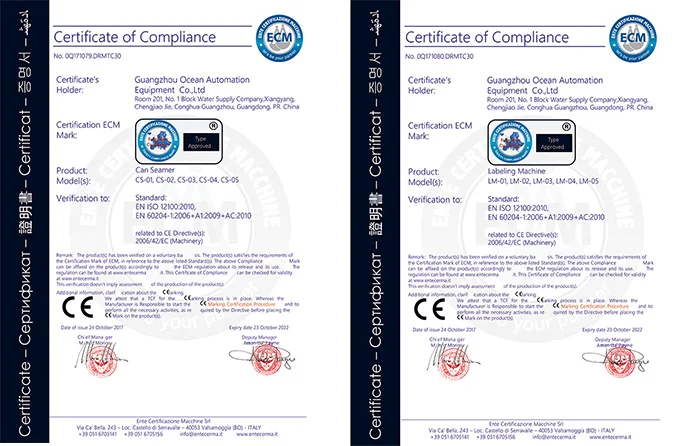

| Yes, Our technical department can help to analysis, design and test the new products you offered. | Yes, we have some, like CE / SGS. |